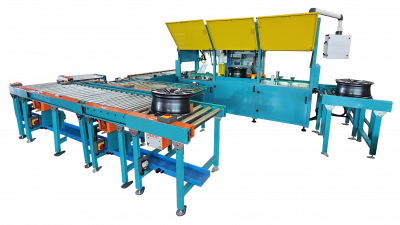

This machine is a tunnel type rim measuring machine designed and produced for use in the automotive industry. It has been developed as a solution to the problem of distortions and twists caused by casting technology in aluminum wheels.

MACHINE CAPABILITIES

- It has been developed to solve the problems of distortions and twists caused by casting technology in aluminum rims,

- The measurement system consists of 3 stages. 1.Valve positioning, 2.Line scan method, 3.Type recognition and measurement system with lazer profile sensor,

- The system is suitable to operate in a completely chaotic manner. Whatever size and type of product comes, the system recognizes it and makes the necessary measurement,

- It assigns the measured results to the nex CNC turning lathe as model information and measurement value,

- The lathes perform the machining according to these values and ensure that the product comes out without errors,

- The system cycle time is 20 seconds.

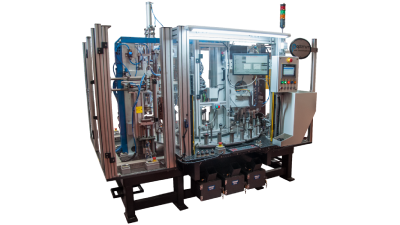

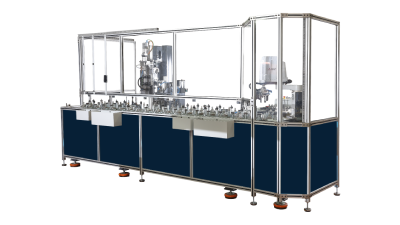

MACHINE IMAGES

MACHINE OPERATION VIDEO