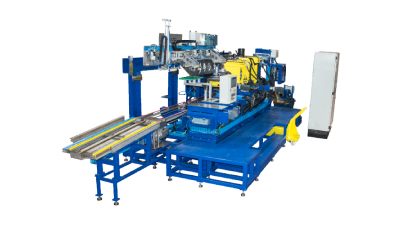

Oven front panel trimming system designed and produced for use in the white goods manufacturing sector, working with 2 separate molds and 34 different models.

MACHINE CAPABILITIES

- Front panel trimming capacity 34 different models working with 2 different molds,

- Cycle time 10 sec ( including operator loading and unloading ),

- Easy and ergonomic product loading and unloading,

- Special production servo press system with 140 Kn 250mm stroke,

- Turntable with 2 molds driven by servo positioning,

- Mold change from the panel ( by entering the product code ) fully automatic in 15 seconds,

- Splecial mold system where all trims are managed by automation and with easy cutter change,

- Mechanical and electrical poke-yoke system t hat prevents the worn product being placed in the molds.

MACHINE IMAGES

MACHINE OPERATION VIDEO