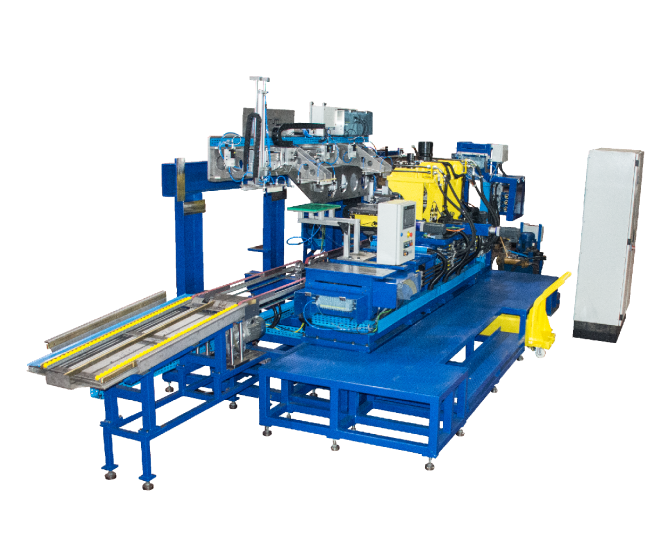

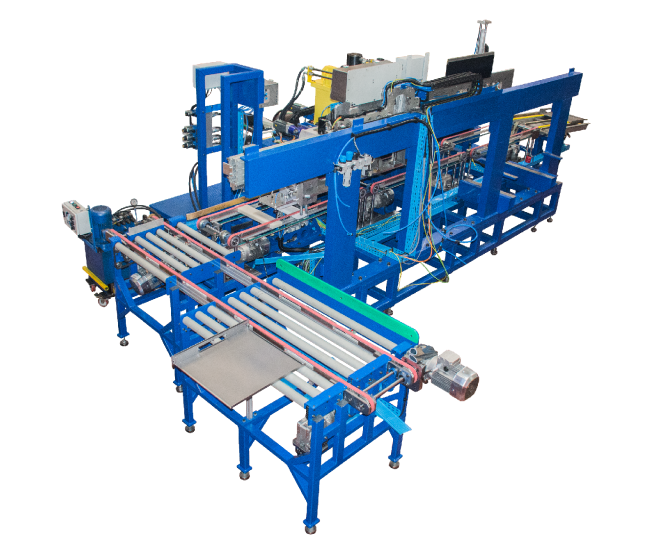

The machine that is designed and manufactured for use in the white goods sector and that trims the refrigerator top sheet panels with the final bending processes completed.

MACHINE CAPABILITIES

- Ability to trim in variable dimensions depending on the width on the refrigerator top sheet panels with 600 – 700 mm width and 20 – 620 mm depth final bending operations completed,

- To be able to perform tox operations in variable sizes depending on the width,

- Model transformation is fully automatic,

- 500 pcs preloaded and sound insulated tox materials sliding system,

- Fully automatic model change (0 – 16 seconds),

- Panel measurement adjustment in depth and width axes (positioning with servo motor)

- Servo + pneumatic product conveying system suitable for Industry 4.0 system,

- Welded construction structure designed with computer simulation according to pressures and flexures,

- Complete stress relieving process,

- Machine cycle time is 10 seconds,

- Baked glass-added epoxy paint.

MACHINE IMAGES

MACHINE OPERATION VIDEO