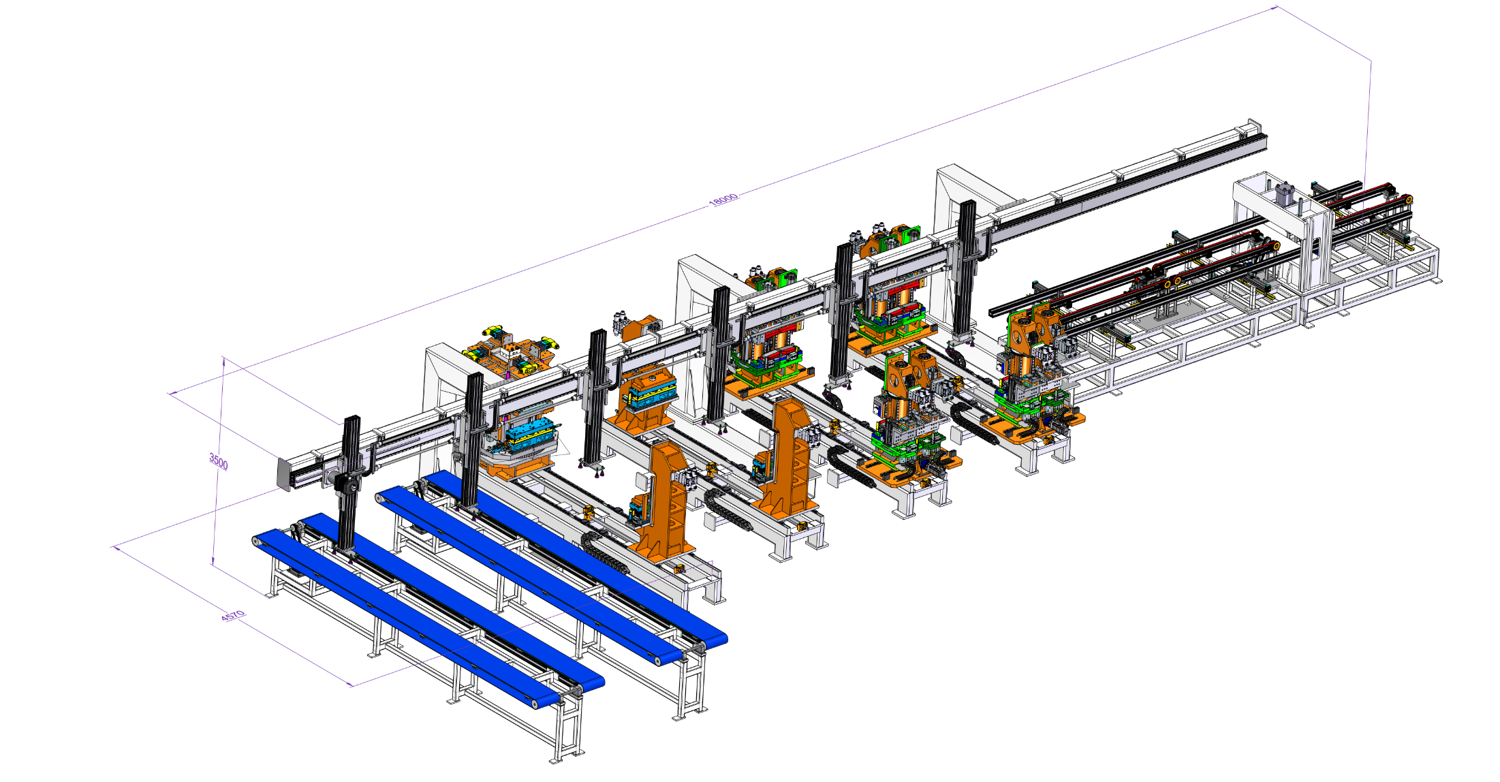

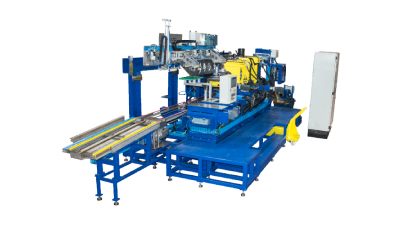

A form line that can perform door profile form and trim operations on the upper and lower door sheets of the refrigerator, which are designed and produced for use in the white goods manufacturing sector and whose final bending processes have been made.

MACHINE CAPABILITIES

- To be able to perform door profile form and trim operations on door sheets with final bending processes in 480 – 950 mm width, 350 – 1800 mm lenghts,

- Ability to trim display or logo from on the door sheet,

- Model change fully automatic,

- Machine cycle times 15 sec,

- Fully automatic model change ( 0 – 10 seconds time )

- Size adjustment from the control panel in all axes and paints ( positioning with servo motor ),

- Sutiable for Industry 4.0 systems,

- Cutting with hydraulic sistem + optional servo cutting system,

- Designed according to pressures and stretches with computer simulation, welding, construction builing,

- Baked glass additive.

MACHINE IMAGES

MACHINE OPERATION VIDEO